Summary:

- Whoever wants to create a fashion collection with no delays or flaws must count on an important document for clothing: the fashion specification sheet (or just “spec sheet”);

- There are different types of fashion spec sheets. Find out how they work, and which one fits best for what you need;

- To enhance the agility of your collection’s manufacturing, Audaces Idea can be a great ally. Get the free trial of the Audaces360 multi-solution now!

When creating a piece of clothing, or an entire fashion collection, there is a vital document for your work to be crystal clear to those involved in the production stage: the fashion spec sheet.

This file contains complete details about each product. Therefore, it helps you understand if the pieces will be viable, what materials will use, which price will be, and much more.

We’ve prepared special content for you to learn the main types, what they are for, which one is the best for you, and how to assemble your fashion spec sheet quite correctly!

Keep reading to find out more!

Sumário

What is a fashion spec sheet, and what is it for?

The spec sheet is part of all stages of fashion production. It integrates the sectors and optimizes the collection development processes, generating benefits and agility for the creation.

This descriptive document contains all possible information about the pieces. It shows the characteristics of the model so that the professionals involved can understand the initial idea, delivering the products according to what was planned.

Here are the main details a fashion spec sheet must have:

- Pieces’ model

- Basic features

- Type of fabric

- Trimmings

- Types of seams

- Raw material

- Other processes involved

The richer your fashion spec sheet is, the easier it will be to understand and get the pieces’ manufacturing right!

Fashion spec sheet’s main types

General spec sheet

The general spec sheet contains the most relevant information for all sectors but in a broader way.

The purpose here is to maintain better communication between those responsible for each activity described and to serve as a guideline for the people involved.

For all production steps to be in sync, the information included in the general spec sheet must be items such as raw materials, costs, deadlines, etc.

With all this data gathered in one place, the production cycle becomes more organized and surely efficient.

Fashion spec sheet focused on departments

A spec sheet focused on departments brings the main inputs for a specific sector. It contains detailed information about each stage, as they have their own activities and team in charge.

In this type of spec sheet, some aspects are key: type of seams, size scale, measurements, trims, and other processes needed.

How to choose the best spec sheet for your business?

First, you must understand your business goals, adapting each fashion spec sheet to what suits the needs of your team.

If a production sector needs access to the data from another, we recommend using the general spec sheet. Now, if someone from the same sector needs more specific information, a spec sheet focused on departments is the best option.

It’s interesting to work with both types, using one or another according to necessity.

Learn more: 4 top tips for a successful fashion collection launch

How can the fashion spec sheet benefit your manufacturing?

Besides integrating all the professionals in garment creation, the fashion spec sheet has numerous advantages. For example, it can help identify the pre-cost of the piece, organize the development, optimize delivery, and increase results.

Document all steps

It is important to detail all the production steps in your fashion spec sheet. Thus, all those involved will be able to identify their activities.

In addition to describing each step, the fashion spec sheet improves communication between the team, allows everyone to follow the proper stages, increases agility, and avoids flaws and losses.

Communicate the collection concept

Everyone involved in the production stages must be aware of the concept of the collection. The fashion spec sheet can help to make that happen!

With the help of the document, chances are the collection will get off the drawing board following what the creative, commercial, and financial teams have planned.

Standardize steps

Standardization avoids impairments for the company. That happens because some steps must be accomplished straight, following a logical sequence.

And be careful: the fashion spec sheet must not contain confusing or missing information. If it presents any disconnected references, it might prejudice the progress of the collection, causing delays or even waste of raw materials.

There’s more to watch out for – you can also standardize your product! With a fashion spec sheet, you can quantify parts, the use of raw materials, and other costs.

Determine costs

Be sure to write down all the costs of your fashion collection manufacturing.

Costs are expenses you will have to produce the pieces, ranging from the raw material to the operating time of the machines (and those in charge of each process).

You must be clear and precise when adding the components of your fashion spec sheet. Wrong or disregarded values for being low, and even the fact of not including the labor expenses can generate calculation errors in the price per piece.

How to assemble a fashion spec sheet?

Each company must adapt the spec sheet according to its needs, as the fields to be filled in may vary. You decide what information about your product is vital.

Learn how to fill in a spec sheet the best way:

1) Header

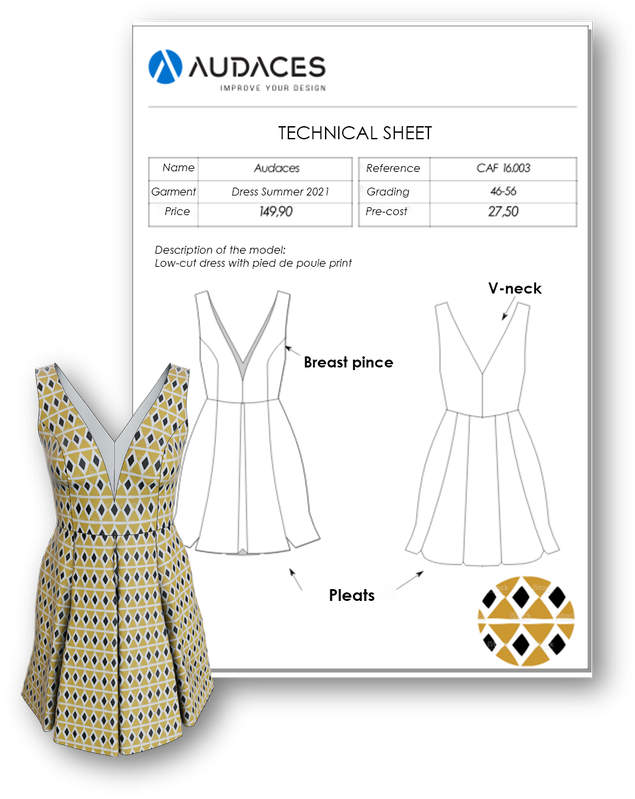

You must start your fashion spec sheet with the header. It should contain the company name, the title of the collection, the name of the piece and its reference, the date, and a brief description of the product.

2) Technical model

After the header, you must proceed to include the technical model of the pattern.

The more information, the less chance of errors. Therefore, place the designs on the front, back, sides and details – if possible, in a larger size – so that the pattern makers and seamstresses can observe everything that is relevant.

3) Raw material

In this step, you must enter which type of raw material the piece will use, the types of fabric and their composition, trims, colors, and sizes.

Here, you can also calculate the spending on these features. Thus, you should include manufacturer and supplier data with the price of each material.

4) Clothing tag

Each clothing tag must have the trading name of the piece, registered trademark, forms of care, conservation and washing, the clothing size, country of origin ,and other relevant data of the company.

5) Printing and/or laundry

If your piece undergoes printing, dyeing, or washing processes outside of the manufacturing, that must also be informed in the spec sheet.

6) Size chart

Finally, insert the size chart and the measurement guidelines for the pieces in the technical sheet.

Learn more: How to make a fashion product catalog in 4 steps

How to avoid mistakes when filling out the fashion technical sheet?

The fashion spec sheet must be assembled with assertiveness to minimize the flaws, which end up affecting your work.

Only this way it is possible to fulfill the spec sheet’s main role: deliver the product on time and properly.

Learn how to avoid failures in your production with the following tips:

Avoid extra amounts of raw material

Try your best to pass on concrete information, without extra amounts of products.

This type of extra information can generate unnecessary costs and wrong conclusions – more products being produced than was planned, for example – or even remove the product from the grid, as it makes production unfeasible.

Bringing the exact amount (or the closest to the exact amount) of raw material, you avoid wasting and help with cost control.

Explore and observe

The more information you provide, the fewer problems, doubts, and rework you will have. When there’s missing information – or unclear – the job becomes harder.

The remarks field is not mandatory, but it is very helpful to align expectations about the development of the piece.

Prioritize clarity

Make no room for (wrong) interpretation! Be as clear and consistent as possible with the information you provide in your fashion fact sheet.

Remember: besides you, other professionals will use the same material in different sectors. A good spec sheet must have detail, precision, and shared information.

Learn more: How to create a perfect technical drawing for fashion

Create a fashion spec sheet for your next collection with Audaces Idea

Do you still create your fashion spec sheets manually? Imagine how much paper and printing costs were spent in this process! (Or better: don’t!)

The good news is software can help your production, 100% digitally – bringing more agility, speed, and economy. Audaces Idea takes care of all that and more!

Audaces Idea’s system improves the products’ creation process. This tool standardizes and brings precision to fashion professionals, making it possible to visualize the collection in 360º, test models, and estimate pre-costs.

This is the only fashion design software that integrates the development of the technical design and the spec sheet. And it also allows sets with variations in the same spec sheet, previewing the costs for each of the parts precisely.

Find out how Audaces products can help you with modeling, planning and creating in a practical and economic way! Download our e-book for free: